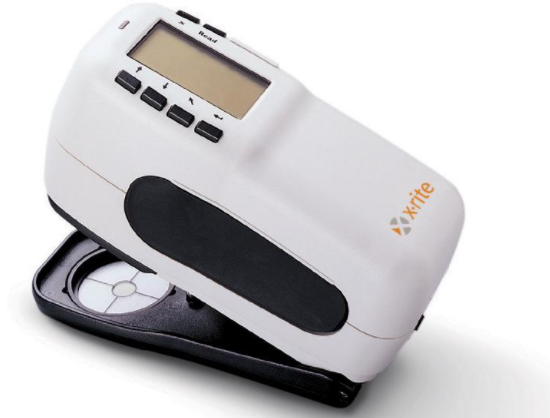

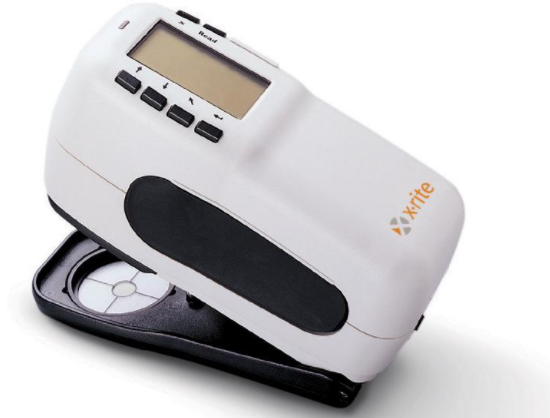

How to maintain sp60 color difference meter?

Sp60 colorimeter is an imported colorimeter, in the long-term use process, there will be various failures. When the colorimeter fails, the user needs to find a professional maintenance manufacturer for troubleshooting. Do not dismantle the machine by yourself.

Analysis of common faults of sp60 color difference instrument:

1: light source aging or damage

Cause: long use time or frequent use.

Solution: replace the light source and correct it.

2: circuit board aging

Cause: long use time or environmental impact

Solution: repair or replace the circuit board

3: the measurement data is not accurate, and the display interface prompts the general system error (A1) and failure to start up, etc.

Product reason: the color and light of the light source are weakened, affecting the accuracy, and there are problems in the measurement procedure.

Solution: after entering a special laboratory for testing, re operate the calibration and write the program.

How to maintain sp60 color difference meter?

The routine system error maintenance of sp60 colorimeter needs to be carried out in a certain environment, which is generally not convenient for door-to-door test and maintenance service. You can express the colorimeter to the maintenance department authorized by the manufacturer for maintenance and correction.

Sp60 colorimeter is generally more durable, and the new machine can be used for 3-4 years. However, for users with higher requirements, the sp60 colorimeter needs to be calibrated every year. Sp60 color difference instrument not only prompts the common system errors, but also prompts the common faults such as insufficient power, dim reading light, etc. in order to ensure the accuracy of the instrument measurement, it needs to be repaired and replaced in time.

Maintenance process of sp60 color difference meter:

1. Maintenance preparation

It is necessary to communicate with the operators of color difference instrument, understand the working condition of the instrument in detail, and improve the maintenance efficiency.

Before maintenance, back up your data; we will not back up and disclose your data, nor be responsible for data loss. Note: restoring factory settings and upgrading will cause the original data to be cleared.

2. Analysis of fault type

Before maintenance, the instrument should be analyzed comprehensively. Find out the fault type of sp60 colorimeter, and check whether it needs to replace accessories, and confirm the final maintenance price with the customer. After the approval of the user, clean and repair the instrument.

3. Video recording of the whole maintenance process

999 instrument maintenance engineer must be trained and qualified before going to work. All the maintenance processes are videotaped to ensure safety.

4, send back

After the repair, it will be sent back by express.