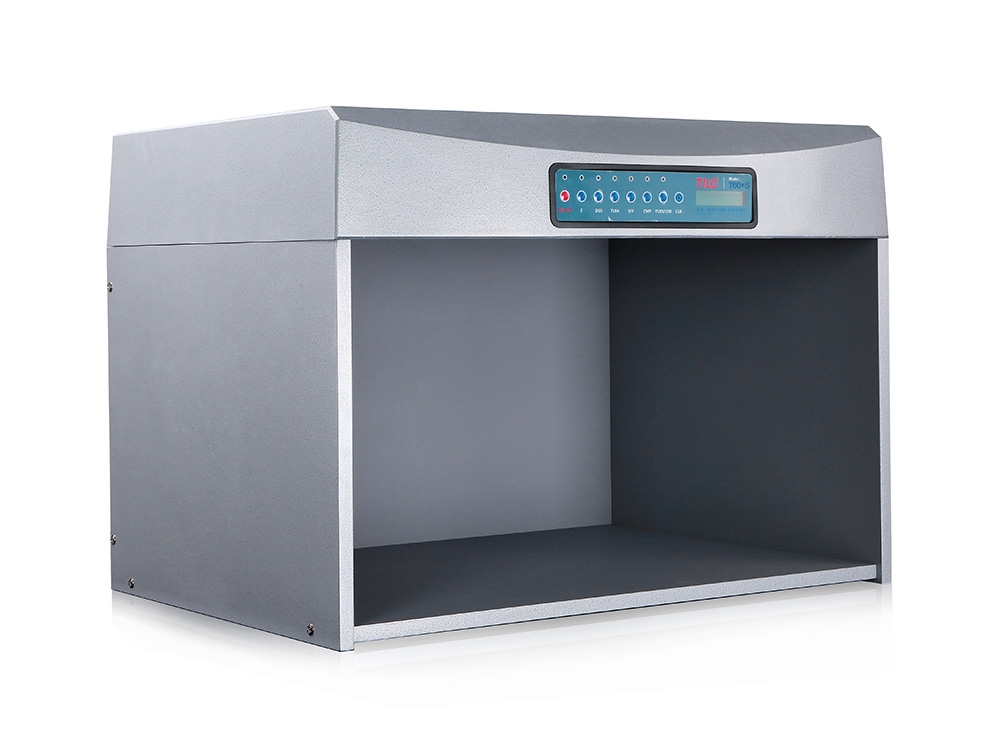

second-handP60+S

- payment:

- WeChat payment Bank card Alipay

Commodity details

In production practice, most of them work under the illumination of light source, and each light source has a certain color. This makes it difficult to correctly judge the color of the manuscript or product. Under the color light, the color changes are generally the same as pale and darkening. For example, under the red light, the color becomes lighter, the red becomes lighter, the Yellow becomes orange, the green becomes darker, the green becomes darker and the white turns red. Under the green light, the color becomes lighter, the green becomes lighter, the green becomes lighter, the Yellow becomes greenish yellow, the red becomes black, and the white turns green. Under the yellow light, the Yellow becomes pale, the magenta turns red, the green turns green, the blue becomes black, the white becomes yellow. Under the blue light, the color is lighter, the blue becomes lighter, the green becomes lighter, the green becomes darker, the Yellow becomes black, and the white becomes blue. In printing workshop, the color temperature is higher (3500~4100K), and the fluorescent lamp with better color coefficient is used as the light source. Therefore, it is very important for industrial producers to have a standard light box which can provide standard light source.

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Name |

Color temperature |

power |

|||

|

D65 international standard artificial daylight |

6500K |

18W |

|||

|

TL84 Europe, Japan and China store light source |

4000K |

18W |

|||

|

CWF American cold store light source ( |

4150K |

20W |

|||

|

F lamp and colorimetric reference light for Hotel Familia |

2700K |

40W |

|||

|

UV lamp source |

365nm |

18W |

|||

|

TL83 America warm white store light source |

3000K |

18W |

|||

Details